nanoERA

The nanoERA machining centre is the ideal solution for micro-mechanical machining, both with three and five axes.

Characterized by an extremely compact structure it’s suitable as a bench machine for easy and prototype operations; with a weight of 240 kg and a 220Vac power supply (single phase) can be housed both in industrial sites but especially in craft-workshops personal.

The machine has a 24,000 RPM spindle with ISO 20 taper that allows processes with high finishing results; already complete in its standard three-axis version, it can have as an option a rotary tilting table with five axes of 100mm diameter.

nanoERA

The nanoERA machining centre is the ideal solution for micro-mechanical machining, both with three and five axes.

Characterized by an extremely compact structure it’s suitable as a bench machine for easy and prototype operations; with a weight of 240 kg and a 220Vac power supply (single phase) can be housed both in industrial sites but especially in craft-workshops personal.

The machine has a 24,000 RPM spindle with ISO 20 taper that allows processes with high finishing results; already complete in its standard three-axis version, it can have as an option a rotary tilting table with five axes of 100mm diameter.

| FEATURES | nanoERA |

| X-Y-Z travel | X: 220 mm Y: 120 mm Z: 200 mm |

| Table dimensions | 460 x 130 mm |

| "T" slots | 38 x 12 mm |

| Tool change | 6 positions |

| Max load on table | 30 Kg |

| Spindle taper | ISO 20 |

| Max speed (standard) | 24.000 rpm |

| Power spindle motor | 2,2 Kw |

| Rapid feed rate of axis | 2.000 mm/min |

| Axis motorizations | 400W brushless |

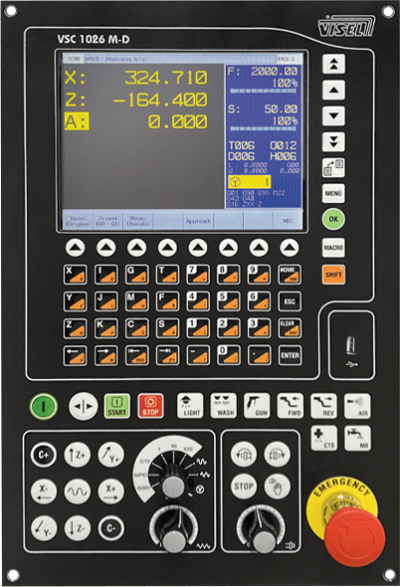

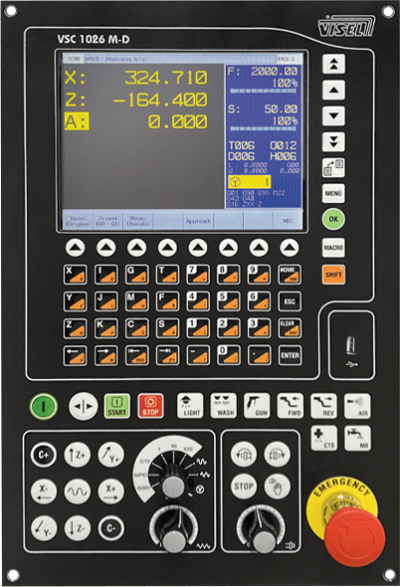

| CNC standard | VISEL VSC 1026 |

| Net weight | 240 Kg |

| Total power supply | 220 Vac |

| Dimensions | 930 x 650 x (h) 850 mm |

Aumento velocità mandrino 36.000 RMP

Cambio utensile + 10 utensili (tott. 32 utensili)

Presetting utensile Z + D (radio)

Compressore silenziato (20 L) 230 Vac , mono fase

KIT Interfaccia ROBOT (In-out digitali)

KIT INDUSTRIA 4.0

Allestimento macchina per lavorazione graffite o materiali polverosi

USER FRIENDLY CNC maximum simplicity with high performance.

Versatile, simple and practical, VISEL CNCs have been designed using criteria of extreme simplicity of use with a practical and intuitive “USER FRIENDLY” operator interface. Extremely complete, they can be programmed at various levels: in standard ISO (G code), for the compilation of pre-defined cycles (MACRO), through direct creation, drawing a profile directly on the machine or importing it from a CAD file in .DXF format with consequent processing. The powerful firmware and innovative architecture allow high tech performance in the complex machining of molds and high-quality parts.

USER FRIENDLY CNC maximum simplicity with high performance.

Versatile, simple and practical, VISEL CNCs have been designed using criteria of extreme simplicity of use with a practical and intuitive “USER FRIENDLY” operator interface. Extremely complete, they can be programmed at various levels: in standard ISO (G code), for the compilation of pre-defined cycles (MACRO), through direct creation, drawing a profile directly on the machine or importing it from a CAD file in .DXF format with consequent processing. The powerful firmware and innovative architecture allow high tech performance in the complex machining of molds and high-quality parts.